DIY Plasterboard Repair

Johnson Brothers Mitre 10 New Store

73 Bassett Street

Mona Vale - Online Store: Jbhmv.Com.Au

DIY Plasterboard Repair

- Place self-adhesive mesh patch over the hole.

- Use a plaster knife to cover the patch with lightweight joint compound in a crisscross pattern, feathering the edges so it blends with the wall.

- Let the patch dry and apply a second coat of compound if needed.

- Sand smooth, ready for a paint finish. Tip: wrap your sandpaper around a flat piece of wood to ensure you have a flat to wall surface. This will prevent gouging a dip in the newly applied plaster.

- Cut a piece of plasterboard panel slightly larger than the hole. Hold the cut plasterboard panel against the wall and trace around, then remove and mark diagonal lines from the corners towards the hole.

- Taking care not to puncture plumbing or electrical wiring, use a plasterboard saw or trimming knife to cut all the way through the diagonal lines. Then firmly run the trimming knife along the straight outline, and push the piece of plasterboard into the opening – this will ‘snap’ the piece off. Use a trimming knife to cut through the backing paper then discard the piece. Continue with each part.

- Cut your second piece of plasterboard into two backing blocks. Backing blocks should be at least 40mm wide, and the height of the hole plus 40mm to allow room for adhesion.

- Using a small amount of Rapid Patch, stick the two blocks of plasterboard to the inside of the wall. Ensure that the cut edges and all adhesive surfaces are clean.

- Leave to dry for at least 1 hour.

- Apply Rapid Patch to the front face of the backing blocks and gently push the new plasterboard panel into place, ensuring the face is level with the existing wall.

- Leave to dry for at least 1 hour.

- Apply Easy Tape to cover the joins between plasterboard panel and wall (sand any painted surfaces first).

- Apply 2 coats of Rapid Patch, leaving 20 minutes drying time and sanding between coats.

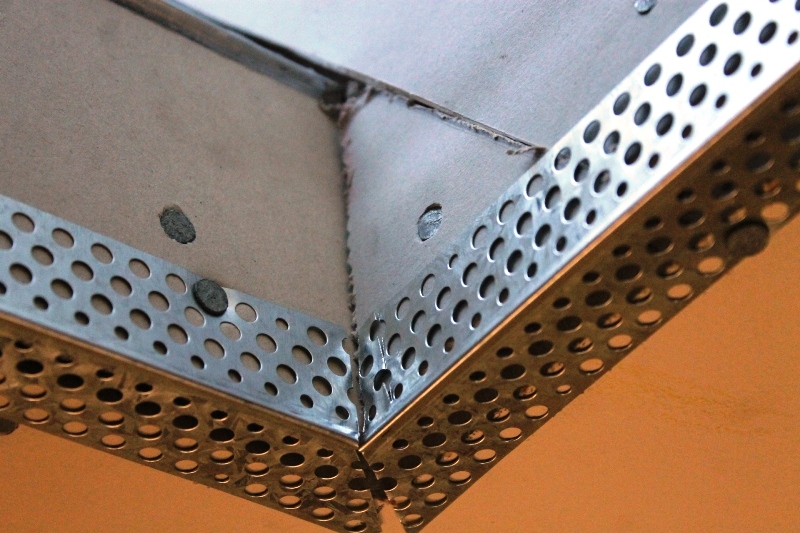

- If you cannot make the edge sharp again, cut out the piece of Gyprock that has become damaged. Position each cut about two inches away from the corner and make both of them long enough to encompass any hairline cracks visible above or below the point of impact. With the repair area outlined, use the hammer and cold chisel to chip off the old joint compound and expose the metal corner bead beneath. Cut out the damaged section with a utility knife or hacksaw to cut through the corner angle; remove a section at least 15 centimetres long around the damage. If the angle is screwed in place, remove the screws and pull it out with pliers. If it's nailed, gently pry it off without crushing surrounding surfaces. If you can't pry out the nails without further damaging the wall, use the snips to cut the bead from around the nailheads. Then pull off the damaged section and tap the nails below the surface with the hammer.

- Measure and cut a New Metal Angle Section

- Fill the gaps in the internal plaster corner. Mix some plaster base coat in a bucket until it has the consistency of toothpaste. Then use your scraper to fill the corner gap between the plaster walls. Make sure you scrape off any excess. Once the base coat is dry, use the scraper blade to take off any small ridges on the base coat.

- Reinforce the internal plaster corner with paper tape. Cut a piece of paper tape to the height of your wall. There will be a crease running down the centre of the tape. Use this to fold the tape in half. Now apply a thin coat of plaster base coat to both sides of the internal corner and press the tape over the top. Once the tape is in place, use your scraper to flatten it onto the wall, squeezing out any excess base coat. Then leave the plaster to dry.

- Apply a top coat to the internal plaster corner Use a paint scraper to apply a top coat of plaster on both corner faces. Run an internal corner plaster tool over the top coat to give it a smooth finish. Leave the top coat to dry. Sand smooth ready for a paint finish.

Products advice is available from the trained friendly staff at Narrabeen, Mona Vale and Avalon Johnson Brothers Mitre 10.

Click on logo to visit Johnson Brothers Mitre 10 website

Johnson Bros Mitre 10 - Avalon (02) 9918 3315

Johnson Bros Mitre 10 - Mona Vale (02) 9999 3340

JBH Timber & Building Supplies (02) 9999 0333

JBH Fencing & Landscape Supplies (02) 9970 6333

www.johnsonbros.com.au Online store: jbhmv.com.au

Previous DIY Pages:

Decking Timbers Caring For Your Deck Decking Finishes Privacy Screens I Privacy Screens II Privacy Screening Hardwoods Autumn Paths and Lawns Insulation Batts Plasterboard Ventilation - Edmond's Ecofan Blackboards for Children and Home Spring Lawn Care Shade Sails & Watering Basic DIY Tools DIY Tools - Power Drills Recycle Your Trampoline into An Air Bed How to Build Your Own Backyard Cricket Pitch Christmas Lights Displays around House and Garden Summer Mildew - Refresh, Renew How to Fix Things That Drip and Bump in the Night Time To Plant Winter Vegetables in a Raised Garden Beds Layout Organsing Your Tool Shed Make Your Own Weathervane Installing A Garden Watering System Decking Oils How To Make Garden Compost How To Winter proof Your Lawn How to create Shabby Chic effect on Timber Furniture How to Build Your Own Raised Garden Bed Growing Your Own Winter Vegies Winter Heating Guide Prepare Your Yard For Winter Eradicating Noxious Weeds From Your Yard How to Fix Furniture Finishes Part I How to Repair Scratches, Dings, and Dents of Furniture Surfaces - Part II Winter Draughts Fix Classic Wooden Tool Carrier Spring Garden Checklist Part I Install Your Own Skylight Retaining Walls for Saving Soil and New Spring Garden Beds Summer Salad Garden Native Plant Garden for A Fairy Arbour Renewing Short Flight of Exterior Stairs Deck Maintenance DIY Summer Tasks You Can Do In Time to Get to the Beach Garden Ponds for Attracting Birdlife, Dragonflies and for the Soothing Sounds of Water Salt Air: Maintenance and Protection Creating an Outdoor Dining Arbour, Gazebo or Patio - Part I Creating an Outdor Dining Arbour, Gazebo or Patio Part II Autumn Garden Tasks Autumn DIY Jobs: Waterproof Your Home Checklist Dealing With Dampness Inside the Home Fixing Your Fence Repairing and Replacing Damaged Decking boards DIY Toy Box and Snow Globes: School Holidays Fun - Winter 2015 DIY Wooden Toy Cars and Perfect Painted Flowerpots: School Holiday Fun - Winter 2015 Shoring Up an Under House Earth Bank – Installing a Basic Retaining Wall DIY One Shelf Sideboard Early Spring 2015 Garden Care Salad Garden For Children Keeping Your Garden and Home Cool in Hot Weather Classic Beach Garden and Camping Chairs 3 Portable Versions Anyone Can Make DIY Outdoor Furniture Mark I: Park Benches for Your Garden Make Your Own Scooter or Skateboard: Summer 2016 Fun How to Install a Solid Core Door and Door Furniture Summer Garden Jobs: Pruning A Hedge How to Make A Swing Chair - With A Frame for Garden Setting Garden Jobs for March to Make A Beautiful and Healthy Spring Keeping Outdoor Nooks Warm During Cooler Months Children’s Step Stool with Storage Stop Winter Rain Lawn Loss and Soil Erosion on Slopes DIY Garden Shed: Part 1 of 4 - Base DIY Garden Shed: Part 2 - Framing Walls DIY Garden Shed: Part 2b - Gable Roof Framing Garden Shed Part 3: Roof Installation DIY Garden Shed: Weather- boards - Door And Window Installation And Paint Finish DIY Coffee Table With Chessboard Inlay Spring Gardening: Feeding Your Soil And Plants - What Works For Each Plant DIY Sandstone Flagging Parking Area - Platform DIY Pre-Summer Checklist For A Safe Home Summer Spruce Up: Interior Paint Tips and Three easy steps to rejuvenate your timber deck The Perfect BBQ Garden Setting DIY Water Wise Garden DIY Side Gates DIY Storm Preparation And Home Protection One To Two Day DIY Weekend Spruce Ups Vegepods For Autumn Planting + Easy To Make Lego Table Or Student Desk That Can Be Dismantled + Johnson Brothers Mitre 10 Online Store Johnson Brothers Mitre 10 Great New Mona Vale Store: Still In Bassett Street - number 73 Johnson Brothers Mitre 10 New Mona Vale Store: The Greenlife Garden Centre Go Outside And Play: Creating Garden Spaces To Connect Children With Nature

______________________

John and Bob Johnson - The Johnson Brothers Profile John William Alfred Johnson - The Eulogies for those who could not attend Mass

Australia's Prime Minister Visits Mackellar - Informal Afternoon Tea with Hon. Malcolm Turnbull October 2016

Copyright JBH Mitre 10, 2017. All Rights Reserved.