Decking Oils

By Paul Johnson

Summer is on our doorstep, and with it comes the season to entertain. Pittwater residents love their timber decking and with a bit of simple maintenance you can have your friends and family green with envy as your deck glistens all summer long.

While timber decking can look amazing, if un-kept it becomes grey and tired, increasing its susceptibility to rot, crack, and absorb stains. For this reason it is vital to maintain the coating that has previously been applied.

Think of your timber as living and breathing. When you pull a branch from a tree it is full of oils that make it supple and strong allowing it to bend and withstand impacts without snapping or denting. A piece of deadwood that has dried out will snap under pressure and easily dent and crack. The same principle is applied to your timber deck.

Decking oils are designed to bring timber back to its natural state by providing a rich substance that the timber can soak up bringing it as close as possible to its original “green” state. Oiling your deck can even bring old tired timber decking back to its original colour, strength and impact resistance by following these simple steps.

CHOOSE YOUR PRODUCT.

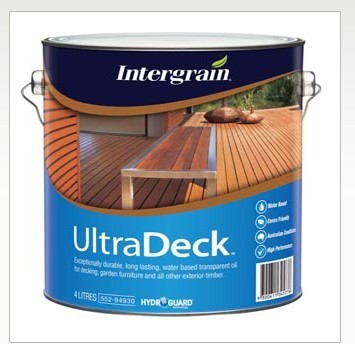

The most important choice to make is whether you want a water based, or oil based product. Traditionally oil based products were preferred as they lasted longer and provided the timber with a richer look. However, with pressure from the government to make products more environmentally friendly water based products have superseded the oils in durability. Intergrain’s “Ultradeck” is the most durable product available in the Orica wood care range and happens to be a water based product. Some people do still prefer the look and feel of the oils as they provide a more natural texture.

The best advice is to head into Johnson Brothers and look at our pre made timber samples that show the look and feel of each product on different types of timber.

CLEAN YOUR DECK.

Fungi spores, walked in dirt, saps, and residue chemicals will slowly build up on the surface of your deck over time, suffocating your timber. It is essential that these are removed before applying any oil as their presence prevents the product from penetrating the timber and replenishing it as it is designed to do.

There are a few options when it comes to cleaning your deck. Cabbots, Feast Watson, and Intergrain (all available at Johnson Bros Mitre10), all have their own liquid solutions that contain either one, or a combination of; Oxalic acid, hydrochloric acid, and bleach. When used according to the directions (usually one part product to four parts water), these diluted chemicals will kill any unwanted fungal spores and lift out in ground dirt and stains.

Apply these products with a stiff bristled scrubbing brush by dipping the brush into the solution and then transferring it straight onto the timber surface. This is vital as it forces the product into the top layer of the timber. Leave the product on the surface for 10-15 minutes and then rinse clean with full pressure on your hose or with a pressure sprayer.

APPLY YOUR PRODUCT.

Applying your product correctly is vital in order to achieve an even finish. Make sure your timber has been allowed to dry completely and do not attempt to apply you product if rain is scheduled. Even

uncured oil based products are affected by rain; since oil naturally floats on water it will lift your product off the deck leaving it patchy. There are a few options when it comes to applying your product.

Applying with a brush is time consuming but forces the product deeper into the timber and gives it a longer lasting finish.

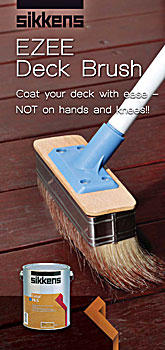

Decking applicators are a pad that is on a long handle and allows you to cover greater areas in less time without bending over. If you do use these applicators it is vital that you apply a medium pressure so that the product is pushed into the surface rather than floating across the top.

Sikkens also make a decking brush that is attached to a pole and provides great coverage while the bristles force the product into the timber providing a better finish that lasts longer.

No matter what applicator you use it is vital that you apply the product in the same direction of the timber and use the fewest strokes possible. The edge between new product and dry timber must always be kept wet. If the product is allowed to dry in a section before the adjoining section is coated a line will become visible in the finished product where the dried coat was overlapped by the wet coat.

Once the first coat is applied it must be left to dry in accordance with the individual products specifications before a second coat can be applied.

Many people try to get away with applying only 2 coats in order to save time and effort however this is counterproductive. The first coats will be absorbed into the timber and will strengthen and enrich it from inside out, however, while the timber will once again be strengthened, this surface coat is what suffers the effects of UV rays, salt spray, heat, rain, staining, and of course foot traffic.

The final coat is needed in order to provide surface protection for the decking; it is this coat that makes the difference between a year long “brand new” appearance, and a weathered appearance in 3 months time.

Now that you have all the information you need you can make your deck a piece de resistance this summer, and the whole year through.