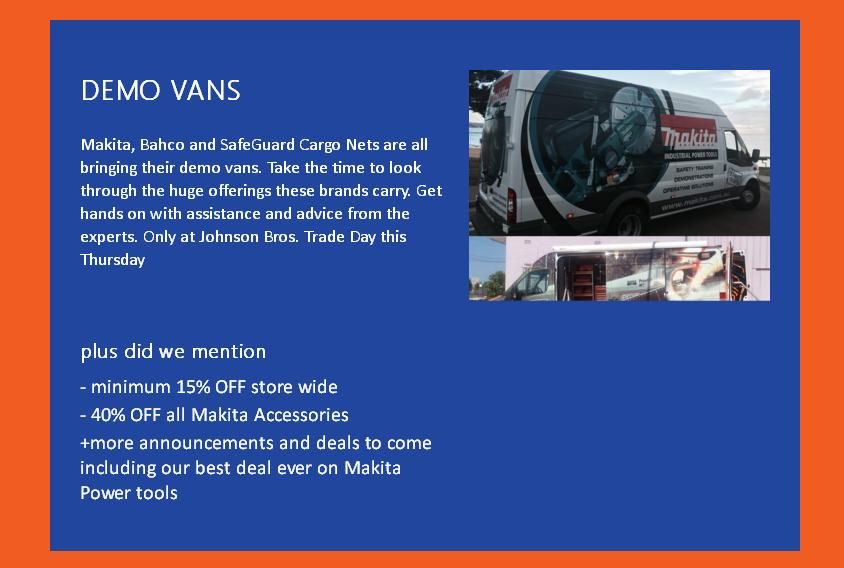

DIY Garden Shed: Part 2 - Framing Walls

Backyard shed – Artists Studio

Approx: less than 10k if do labour bulk of work by self

Part 2a: Framing - Walls

1. formwork/concrete slab/pour

2. form up frame - order window (lead time approx. six weeks).

3. roof (has one clearer sheet to allow light in naturally – you could use a skylight option here too) + guttering and rainwater tank.

4. install walls – and paint.

After your concrete slab is finished the next step is Framing. The sizing for 2.4metres x 4metres now has height added to it - you can choose to have a 2.4metre height, or for more air and a larger feel, 2.7m ceiling height, particularly with the gable roof choice, will add extra space. The pitch on the gable roof shown here is 22.5 degrees.

After your concrete slab is finished the next step is Framing. The sizing for 2.4metres x 4metres now has height added to it - you can choose to have a 2.4metre height, or for more air and a larger feel, 2.7m ceiling height, particularly with the gable roof choice, will add extra space. The pitch on the gable roof shown here is 22.5 degrees.

The timber for your frame will be the largest outlay cost wise for this project. The weatherboard cladding is next. It is important to get enough timber to get the job done but stick t the Tradies 'measure twice and cut once' to minimise the wastage.

The framing will run in two parts - Wall Framing and then Roof Framing.

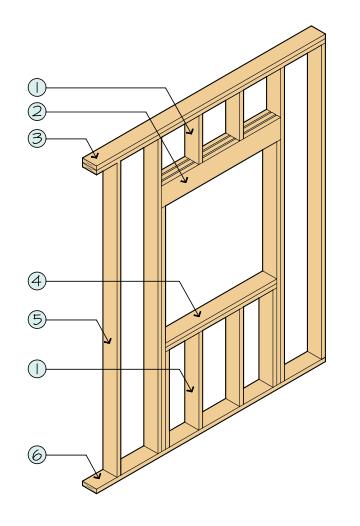

Parts of a Wall Frame

1. Stud - 2. Lintel - 3. Top plate / upper wall plate - 4. Window sill/Sill trimmer - 5. Stud - 6. Bottom plate. 7. Noggins(the horizontal bracing between the studs.

Framing here takes two parts - the walls and the roof frame. Always choose a H2 TR Pine - H2 treated pine is specially treated to protect against borers and termites, making it very suitable for wall framing and roof trusses.

You will need structural posts for each corner of the shed and for the roof.

The framing upright timbers - Studs - are built in 90x45 Treated Pine. The Noggins are built in 70x35 H2 Treated Pine. The lengthways roof rafters are 140X35 treated pine - called a 'Rougher Header.

Don't panic if this seems complicated, it's not. Johnson Brothers Hardware have trained staff and if you give them your dimensions they can provide you with a quote on what timbers you will need and in what quantities and what will work best, not only for your own needs, but to meet Australian Standards and Building Requirements.

Working out how much timber you need for framing

For the shed shown here you will have Structural Timbers, Studs

Wall ends - 2 x 9 at 2m

Length of Wall in metres 2m + Height of Wall in metres 2.7 Total Area m2 5.4 = linear meters of stud at 400mm centers: 20.2 with 15% waste: 23.2

Total 46.4 Lineal metres for the short end walls

Top side beams/upper wall plate and Bottom Plate: 4 x 2m

Wall sides (lengthway) 2 x 12 at 2m

Length of Wall in metres 4m + Height of Wall in metres 2.7 Total Area m2 10.8 = linear meters of stud at 400mm centers: 37.7 with 15% waste: 43.4

Roof 2 x 10 at 1.2 metre rafters on either side of the main beam (called a rougher header) PLUS a . 350mm Eave for the Gable Ends. The Rafters areat 600 Centres and at a 22.5 pitch. PLUS the structural beams you see running the length of the shed roof in the photos below. These are all the same length as the longways wall side and remain inside the structure - 4 x 4 metres + centre header.

Rafters: 20 x 1.7m (allow for wastage and to cut at an angle.

Structural Beams: 4 x 4 metres + centre header. NB: We used MGP10 PINE H2 TR LOSP 90X45 2.4M -4M - 20. LM for the Structural Beams.

Calculating Key Points in your Wall Frames

Measure the width and height for your door and allow for door jamb. The door to be installed here is a solid core door: 2040(height) X820 (width)X35 (thickeness of door)

Also take into account when building this stage of your framing that a clear perspex sheet of roofing is going to be inserted to allow extra light into the room space and allow for framing of that.

Apply a similar method when measuring for the window cavity.

In this project the Stud Opening Size is : "Height", 960 mm,"Width",1000 mm x 2. The Lead Time on ordering windows can be up to six weeks, so it is worth taking this into consideration at this stage. The usual process is a 50% deposit and the remainder to be paid prior to delivery. THe cost here is approximately $650.00 for the two windows.

Roof framing - interior view - this shows the sisilation paper - which will form part of No.3.

Gable end roof rafters

Ends of lengthway sides of shed gable ends

Materials and Tools List

Apart from the timber required for the walls you will need concrete screws for the Base board, nails for the framing

Cut your timber

Cut your timber

While council regulations will vary, there are some general rules for shed building that apply throughout most of Australia:

1. A 10 square metre or smaller shed probably will not require council approval. In some areas the maximum size can be as small as 9sqm and in others as much as 20sqm.

2. In rural areas, it is often possible to build a shed as large as 50sqm without obtaining council approval.

3. Sheds lower than 2.4 metres in height do not require council approval in many areas.

4. If a shed is located more than 900mm from adjoining properties, council approval will probably not be required.

5. If you live in a heritage conservation area, a shed can be constructed in the back of the property.

6. In bushfire prone areas, sheds must be constructed of non-combustible materials if it is located within 5 metres of the main dwelling.

7. The size, shape and location of the shed must not make it dominate the surrounding landscape.

8. Sheds are defined as non-habitable structures.

While a shed is a relatively informal structure, it still must be built to minimum Building Code of Australia (BCA) standards.

Is Shed Building a DIY Project?

Sheds are relatively easy structures to build and as long as you include a cement slab and build a small, soundly constructed shed, it can be a viable DIY project. However, many do-it-yourselfers are finding it easier and less expensive to buy kit shed from shed suppliers. Timber, metal and aluminium shed designs are available and they can be customised with shelving, ventilation systems and other extras to suit your needs.

What is Exempt Development?

Some minor building renovations or works don’t need any planning or building approval. This is called exempt development. Exempt development is very low impact development that can be done for certain residential, commercial and industrial properties. A few examples of development that can be exempt development are: decks, garden sheds, carports, fences, repairing a window or painting a house. As long as the proposed works meet all of the development standards (identified in the State Policy for exempt and complying development), approval may not be needed.

Exempt and complying developments NSW Govt webpage

Exempt developments: NSW Govt. webpage

Check project: Electronic Housing Code – NSW Govt. Service

Minor works around the home (Exempt Development)

1. Cabanas, cubby houses, garden sheds, greenhouses etc

2.18 Development Standards (1) The standards specified for that development are that the development must: (a) (Repealed) (b) not have a floor area of more than: (i) on land in Zone RU1, RU2, RU3, RU4, RU6 or R5—50m2, or (ii) on land in any other zone—20m2, and (c) be not higher than 3m above ground level (existing), and (d) be located at a distance from each lot boundary of at least: (i) for development carried out in Zone RU1, RU2, RU3, RU4, RU6 or R5—5m, or (ii) for development carried out in any other zone—900mm, and (e) if it is not on land in Zone RU1, RU2, RU3, RU4 or RU6—be located behind the building line of any road frontage, and (f) not be a shipping container, and (g) be constructed or installed so that roofwater is disposed of without causing a nuisance to adjoining owners, and (h) to the extent it is comprised of metal components—be constructed of low reflective, factory pre-coloured materials if it is located on land in a residential zone, and (i) if it is located on bush fire prone land and is less than 5m from a dwelling—be constructed of non-combustible material, and (j) if it is constructed or installed in a heritage conservation area or a draft heritage conservation area—be located in the rear yard, and (k) if it is located adjacent to another building—be located so that it does not interfere with the entry to, or exit from, or the fire safety

Products advice is available from the trained friendly staff at Mona Vale and Avalon Johnson Brothers Mitre 10.

Click on logo to visit Johnson Brothers Mitre 10 website

Johnson Bros Mitre 10 - Avalon (02) 9918 3315

Johnson Bros Mitre 10 - Mona Vale (02) 9999 3340

JBH Timber & Building Supplies (02) 9999 0333

JBH Fencing & Landscape Supplies (02) 9970 6333

vegepod made into a fail-safe herb garden - at Johnson Brothers Hardware Mitre 10 Mona Vale

Previous DIY Pages:

Decking Timbers Caring For Your Deck Decking Finishes Privacy Screens I Privacy Screens II Privacy Screening Hardwoods Autumn Paths and Lawns Insulation Batts Plasterboard Ventilation - Edmond's Ecofan Blackboards for Children and Home Spring Lawn Care Shade Sails & Watering Basic DIY Tools DIY Tools - Power Drills Recycle Your Trampoline into An Air Bed How to Build Your Own Backyard Cricket Pitch Christmas Lights Displays around House and Garden Summer Mildew - Refresh, Renew How to Fix Things That Drip and Bump in the Night Time To Plant Winter Vegetables in a Raised Garden Beds Layout Organsing Your Tool Shed Make Your Own Weathervane Installing A Garden Watering System Decking Oils How To Make Garden Compost How To Winter proof Your Lawn How to create Shabby Chic effect on Timber Furniture How to Build Your Own Raised Garden Bed Growing Your Own Winter Vegies Winter Heating Guide Prepare Your Yard For Winter Eradicating Noxious Weeds From Your Yard How to Fix Furniture Finishes Part I How to Repair Scratches, Dings, and Dents of Furniture Surfaces - Part II Winter Draughts Fix Classic Wooden Tool Carrier Spring Garden Checklist Part I Install Your Own Skylight Retaining Walls for Saving Soil and New Spring Garden Beds Summer Salad Garden Native Plant Garden for A Fairy Arbour Renewing Short Flight of Exterior Stairs Deck Maintenance DIY Summer Tasks You Can Do In Time to Get to the Beach Garden Ponds for Attracting Birdlife, Dragonflies and for the Soothing Sounds of Water Salt Air: Maintenance and Protection Creating an Outdoor Dining Arbour, Gazebo or Patio - Part I Creating an Outdor Dining Arbour, Gazebo or Patio Part II Autumn Garden Tasks Autumn DIY Jobs: Waterproof Your Home Checklist Dealing With Dampness Inside the Home Fixing Your Fence Repairing and Replacing Damaged Decking boards DIY Toy Box and Snow Globes: School Holidays Fun - Winter 2015 DIY Wooden Toy Cars and Perfect Painted Flowerpots: School Holiday Fun - Winter 2015 Shoring Up an Under House Earth Bank – Installing a Basic Retaining Wall DIY One Shelf Sideboard Early Spring 2015 Garden Care Salad Garden For Children Keeping Your Garden and Home Cool in Hot Weather Classic Beach Garden and Camping Chairs 3 Portable Versions Anyone Can Make DIY Outdoor Furniture Mark I: Park Benches for Your Garden Make Your Own Scooter or Skateboard: Summer 2016 Fun How to Install a Solid Core Door and Door Furniture Summer Garden Jobs: Pruning A Hedge How to Make A Swing Chair - With A Frame for Garden Setting Garden Jobs for March to Make A Beautiful and Healthy Spring Keeping Outdoor Nooks Warm During Cooler Months Children’s Step Stool with Storage Stop Winter Rain Lawn Loss and Soil Erosion on Slopes DIY Garden Shed: Part 1 of 4 - Base

______________________

John and Bob Johnson - The Johnson Brothers Profile John William Alfred Johnson

Copyright JBH Mitre 10, 2016. All Rights Reserved.