Power Drills – DIY Tools 101

Now that we’ve shared with you what most tradies recommend you have as a basic DIYer’s tool kit we’d like to look at the various uses of some of these. This week we’ll begin with Power drills.

The best choice of drill or screwdriver for you depends a lot on what kind of job you want to do-whether it’s general lightweight DIY or more heavy-duty work. You also need to consider how much you want to use the tools and what you want to get out of them-this will determine the type of tool and the price. As in all things, you get what you pay for and if you’re planning to use your tools long-term it’s best to buy the best and look after them. There are several different types of power drills and screwdrivers as well as many that combine the task of drilling and screwdriving. We will look at those that may suit those wanting something more all-purpose.

If you need a drill and screwdriver for a large range of jobs, then those who use them daily recommend upgrading to a model with additional features which will save you money in the long run, such as a reversible option when using as a screwdriver. These power tools take the effort out of your DIY jobs and will help you to get your job done quickly, easily and more accurately.

Corded or Cordless

A general rule of thumb

is that cordless tools are less powerful than corded ones. However, they are

lightweight, easy to use and versatile, so a cordless model with a rechargeable

battery will be the best option for general DIY. Also read up on how long the

battery will take to recharge (measured in hours) as you don't want to be

hanging around when you're ready to start your DIY job. The corded models will

give you more power and torque so will be better for heavy-duty drilling and

more frequent use-you will also benefit from more enhanced features on the

mains-powered drills. If you want to be able to do small quick jobs and be able

to get at inaccessible areas, the cordless version is going to prove to be safer

and more along the lines of what you need.

Percussion Drills

A percussion drill

performs hammer and drill functions and is suitable for use with screwdriving

jobs into metal and wood. The high torque and impact force means that you'll get

the best performance. This drill is ideal as a general purpose drill and is

great for most DIY jobs around the house.

Ease of use to Person

Your tools should feel

easy to hold and comfortable in your hand. Consider factors such as weight, size

and whether it has an ergonomic design, or features soft grip. Most drill models

will have three distinctive handle styles. The pistol grip is the most

traditional and, generally the preferred choice. The T-handle offers better

balance and less wrist strain. The third style is the right-angle hold which is

designed for use in a restricted space. A great way to get more of a 'feel' for

the tool is visit the store and lift them. Talk to staff and get their advice on

which is going to work best for you.

Power rating

Power is measured in voltage

for cordless and wattage for corded models in drills. The higher the wattage or

voltage, the more powerful the tool, so for heavy-duty work it is advisable to

opt for a corded model which also avoids the risk of overheating. Voltages range

from 7.2 to 24 volts and the higher the voltage, the quicker you will complete

your work, although as a general rule, the battery needed will also be heavier.

A larger battery does not necessarily mean that the tool will operate for

longer.

Drill speed

The speed of the drill or

screwdriver is measured in RPM (revolutions per minute) and is really important

to the overall performance of the tool. For budget options there will usually

only be one speed, which may not be enough to tackle tougher materials. A

variable speed control will give you more flexibility to allow you to match the

speed to the material that you are using.

Most experienced users of drills

recommend you start drilling slowly and gradually increase the speed to achieve

the best accuracy. If the drill has a ‘fast stop’ this will enable the drill to

stop quickly as soon as the trigger is released, making the finish much

neater.

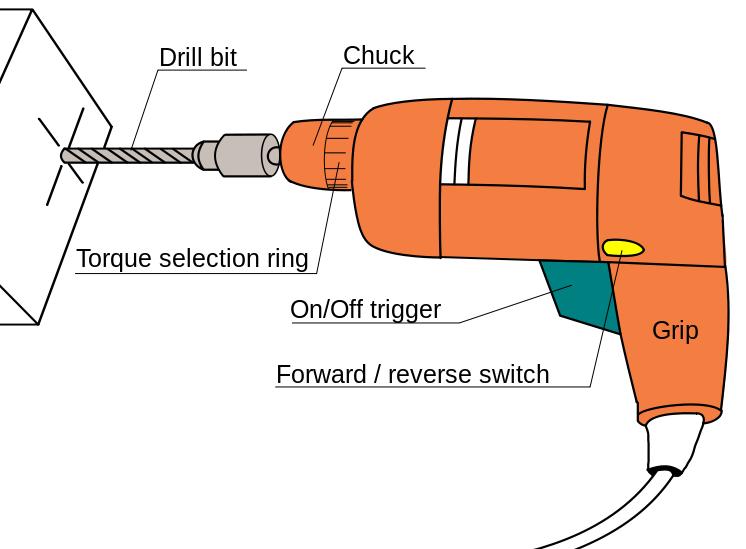

Chuck type and size

The chuck is the

mechanism that attaches the drill bit securely in place. There are 3 main types

of chuck: keyless, keyed and SDS. The capacity of the chuck will dictate the

largest size of drill bit or a particular accessory associated with the drill. A

minimum of 10mm is adequate for most purposes. For keyless chucks, a 13mm chuck

will come with most drills as standard and this allows you to change the drill

or screwdriver bits without the need for a special key to release and tighten

them. You can change drill bits quickly and easily which is ideal if your job

involves lots of different tasks. For key-operated chucks, this means that you

use a specific key to tighten the drill which, whilst this may take slightly

longer to action, will ensure that you can lock the drill bit in place tightly

and prevent slippage. An SDS lock is designed for higher specification models to

avoid slippage and to also withstand the force of its hammer action as it drills

into hard materials such as concrete. Most models will come instructions on how

to safely release or tighten drill bits. If unsure, check with staff prior to

leaving the store.

Gears and torque

The gears in a drill work

along the same lines as gears in a car-they transmit power from the motor to the

chuck and finally to the drill bit. If you are doing general light drilling,

then 1 gear will suffice and this will be the standard for the simplest and

cheapest drills. If you want to use the drill as a screwdriver then it’s best to

pay extra for the second gear. This will enable you to have greater torque

(twisting force) at lower speeds whilst drilling at a lower torque at a higher

speed. Third gears are available but these are usually on the more advanced

models that are designed with the professional in mind. With regard to torque

settings, most drills will come with five as standard which will be suitable for

use on a range of materials. There is also a reverse gear which is great for

undoing screws or freeing jammed drill bits; a quick and easier alternative to

manually trying to do this task.

Drill bits

Correct drill bits are essential

as each is designed specifically for various different tasks. Use the wrong

drill bit and you will get the wrong result. These are:

• HSS (High Speed

Steel)

This is a general purpose bit which can be used on metals, wood and

plastic.

• Wood drill bits (Bradpoint): This bit is used for accurate

drilling in all types of hard and soft wood.

• Flat Wood drill bits: These

bits are used for drilling large diameter holes in all types of hard and soft

wood.

• Auger bits: These are ideal for drilling large-diameter deep holes in

wood or man-made materials and the spiral cutting edge enables fast waste

removal from the previous cut circle.

• Masonry: As the name suggests, this

is designed for drilling through masonry such as brick, stone and concrete.

•

Multi-Purpose: This is used for drilling wood, masonry and plastic and is ideal

for use on a variety of different materials.

• Glass and Tile: This is

specific to drilling glass, tiles and mirrors.

• SDS: These are for use with

all SDS drills and are designed to avoid slippage.

For further product advice on which drill is right for you, pop into Johnson Brothers and talk to the friendly trained staff at either their Avalon or Mona Vale stores.