August 9 - 15, 2015: Issue 226

DIY One Shelf Sideboard

If you have ever wanted to build your own furniture this simple idea may be a good place to start.

This idea celebrates the timber used and will last for decades, even longer. Ours was built 16 years ago from old Oregon Structural Beams but you can still purchase hardwoods that make a feature piece in any home. The timber you choose, and the finish you apply, determines how the piece will look and what colour it will be. Johnson Brothers Mitre 10 at Mona Vale have a wide range of hardwoods – visit and speak to the friendly trained staff in this department and they can advise you on what may work best for what you want to build.

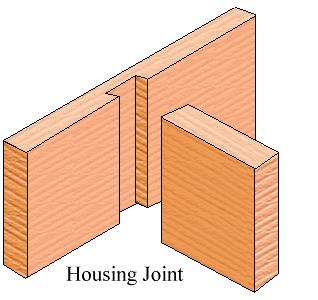

The main skill you will need to pay attention to in this DIY project is making what are called ‘Mortice’ or ‘Housing” joints – that’s where the pieces of wood are fitted together. You can also apply a nice indent or ‘groove’ to the edge of the wood

The version we’ve used is known as a housing joint. A housing joint is used when the entire width of a board is to be slotted into another. Housing joints are perfect for shelving as they distribute the force applied evenly over the length of the joint.

This joint is also used with other materials. For example, it is a traditional method for stonemasons and blacksmiths. (1)

Materials

1 x 224 (length) x10cm (thickness) x 41cm (width) cm – Top shelf

1 x 188 (length) x 10cm (thickness) x 41cm (width cm – Inner shelf

2 x 78 (length) x 8cm (thickness) x 41cm (width) cm – Legs

Wood glue

Stain or varnish of your choice

Sandpaper

Irwin 8 Point Hard Hand Saw: $9.98 - 500mm, 8 point, Constructed from 0.85mm premium cold rolled Swedish steel, Surface treated for 4 x better rust resistance, Hardpoint razor sharp teeth - last 6 times longer than non-hardened teeth

Irwin 8 Point Hard Hand Saw: $9.98 - 500mm, 8 point, Constructed from 0.85mm premium cold rolled Swedish steel, Surface treated for 4 x better rust resistance, Hardpoint razor sharp teeth - last 6 times longer than non-hardened teethRouter – to make groves in edge of shelves - or Hand Plane

Hammer

Chisel

Saw

Eye Safety Protection

Step1: Putting shallow groove into edge of shelf with a Router makes your simple sideboard have a little extra polish. Sand wood edges smooth before routing with edge trimming bits, make sure you are using a sharp bit and running the router and work from left to right, that way, the bit pushes the router toward you rather than pulling it away, so it's easier to control and safer.

Step1: Putting shallow groove into edge of shelf with a Router makes your simple sideboard have a little extra polish. Sand wood edges smooth before routing with edge trimming bits, make sure you are using a sharp bit and running the router and work from left to right, that way, the bit pushes the router toward you rather than pulling it away, so it's easier to control and safer.It can also be good to test making a shallow groove on scrap wood to begin with – that way you can see if you have set the router at the depth you want before ruining your main piece. Another tip is to remove a little at a time – this will prevent the router scorching or burning the timber.

The indent here has been sanded along the edge for added final smoothing. If you are not confident using a router, either leave this step out or use a Hand Plane – but once again – test depth on a practice piece of wood.

Step 2: Mark out a channel with lines across the face where you want the housing joint to be on your legs first. The width of the channel will be the same width as the timber to be inserted into it (8cm in this case). The height between the top shelf and the middle shelf on our piece is 41 cm but you can modify this to suit yourself as long as you bear in mind that the strength or integrity of the piece of furniture needs to be balanced by where you place the joints – keeping these as near to ‘square’ as possible makes it stronger.

Step 3: Cut along the lines with a saw or you can use a table saw for more accuracy. Only cut the channel about half of the depth of your piece of timber: a router could also be used to do this.

Step 4: Once you have cut the channel you now use a chisel and hammer to clean out the excess timber so that the other piece of timber can be inserted into the joint.

Step 5: Clamp up the joint with adhesives and wait until it dries. You can also apply screws and nails to increase strength or to help the joint when applying an adhesive.

Step 7: Cut the channel and again use a chisel and hammer to clean out the excess timber so that the other piece of timber can be inserted into the joint.

Step 8: Clamp up the joint with adhesives and wait until it dries.

Step 9: Give the piece the sandpaper treatment to bring out the grain – it is a good idea to wrap the sandpaper around a flat piece of wood and keep this flat against the timber so you don’t create unwanted deeper grooves on some parts than on others.

Step 9: Give the piece the sandpaper treatment to bring out the grain – it is a good idea to wrap the sandpaper around a flat piece of wood and keep this flat against the timber so you don’t create unwanted deeper grooves on some parts than on others.

Makita 10.8V Li-Ion Mobile Kit; $250.00, QUICK OVERVIEW: Includes drill driver, impact driver, torch, 2 x 1.3Ah batteries, charger, 24 Piece bit set, holster and steel carry case.

Bosch 190W Multi Tool: $179.00; QUICK OVERVIEW: 15,000-21,000rpm, No-load speed, 2.8 degree Oscillation Angle, 4 step depth stop for segment saw blades, Continuously variable speed, Pre-selection for material specific working, Vibration reduction technology, Comes with 10 accessories.

1. Mortise and tenon. (2015, August 5). In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/w/index.php?title=Mortise_and_tenon&oldid=674737064

Products advice is available from the trained friendly staff at Mona Vale and Avalon Johnson Brothers Mitre 10.

Previous DIY Pages:

Decking Timbers Caring For Your Deck Decking Finishes Privacy Screens I Privacy Screens II Privacy Screening Hardwoods Autumn Paths and Lawns Insulation Batts Plasterboard Ventilation - Edmond's Ecofan Blackboards for Children and Home Spring Lawn Care Shade Sails & Watering Basic DIY Tools DIY Tools - Power Drills Recycle Your Trampoline into An Air Bed How to Build Your Own Backyard Cricket Pitch Christmas Lights Displays around House and Garden Summer Mildew - Refresh, Renew How to Fix Things That Drip and Bump in the Night Time To Plant Winter Vegetables â Raised Garden Beds Layout Orgainsing Your Tool Shed Make Your Own Weathervane Installing A Garden Watering System Decking Oils How To Make Garden Compost How To Winter proof Your Lawn How to create Shabby Chic effect on Timber Furniture How to Build Your Own Raised Garden Bed Growing Your Own Winter Vegetables Winter Heating Guide Prepare Your Yard For Winter Eradicating Noxious Weeds From Your Yard How to Fix Furniture Finishes Part I How to Repair Scratches, Dings, and Dents of Furniture Surfaces - Part II Winter Draughts Fix Classic Wooden Tool Carrier Spring Garden Checklist Part I Install Your Own Skylight Retaining Walls for Saving Soil and New Spring Garden Beds DIY Summer Salad Garden Native Plant Garden for A Fairy Arbour Renewing Short Flight of Exterior Stairs Deck Maintenance DIY Summer Tasks You Can Do In Time to Get to the Beach Garden Ponds for Attracting Birdlife, Dragonflies and for the Soothing Sounds of Water The Salt Air Factor: Maintenance and Protection Creating an Outdoor Dining Arbour, Gazebo or Patio - Part I Creating an Outdor Dining Arbour, Gazebo or Patio Part II Autumn Garden Tasks Autumn DIY Jobs: Waterproof Your Home Checklist Dealing With Dampness Inside the Home Fixing Your Fence Repairing and Replacing Damaged Decking boards DIY Toy Box and Snow Globes: School Holidays Fun - Winter 2015 DIY Wooden Toy Cars and Perfect Painted Flowerpots: School Holiday Fun - Winter 2015 Shoring Up an Under House Earth Bank – Installing a Basic Retaining Wall

______________________

John and Bob Johnson - The Johnson Brothers Profile John William Alfred Johnson - The Eulogies for those who could not attend Mass

Copyright JBH Mitre 10, 2015. All Rights Reserved .