Mona Vale Road Upgrade: the machines helping Build the road – For Younger readers

This is a story about the road-building machines we included in last Issues’ Pictorial. Some of our younger Readers have asked us ‘but what’s that one and what is it used for?’ so it seems best to put it all in a page for you. We didn’t get ALL the machines being used – but here’s some insights into those we did, and a bit more, for those who want to know more.

The contractors doing the work state, via regular updates to the community, they are using excavators with rock hammers, backhoes, tipper trucks, small cranes, hammer drills, a roller, street sweepers, chainsaws, light vehicles and light towers.

First, as we know you may not be interested in the History page series currently being put together and near completion on Pittwater Roads and Street Names (and where they came from as part of roads being built to homes when all this area was changing from being paddocks and bush into suburbs), a little about the History of roads themselves.

Some believe that some roads originated from following animal trails – animals that may have been moving in large herds to and from places where they ate, for instance, grass during Summer and then moved across a large tract of land to eat berries, elsewhere, during Winter. The Icknield Way may exemplify this type of road origination, where human and animal both selected the same natural line.

The Icknield Way is an ancient trackway in southern and eastern England that goes from Norfolk to Wiltshire.

By about 10,000 BC human travellers used rough roads/pathways. The world's oldest known paved road was constructed in Egypt some time between 2600 and 2200 BC, however Stone- paved streets appear in the city of Ur in the Middle East dating back to 4000 BC and Corduroy roads (log roads) are found dating to 4000 BC in Glastonbury, England.

Another ancient road is the Sweet Track, a timber track causeway in England, stated by many to be one of the oldest engineered roads discovered and the oldest timber trackway discovered in Northern Europe. Built in winter 3807 BC or spring 3806 BC, (tree-ring dating – dendrochronology – enabled very precise dating), it was claimed to be the oldest road in the world until the 2009 discovery of a 6,000-year-old trackway in Plumstead, London.

The proverb ‘all roads lead to Rome’ makes us think about all the roads Romans (Italians) built as from about 312 BC, the Roman Empire built straight strong stone Roman roads throughout Europe and North Africa, in support of its military campaigns. At its peak the Roman Empire was connected by 29 major roads moving out from Rome and covering 78,000 kilometers or 52,964 Roman miles of paved roads. So, as you can see, all roads did, literally, lead to Rome.

In the 8th century AD, many roads were built throughout the Arab Empire. The most sophisticated roads were those in Baghdad, which were paved with tar. Tar was derived from petroleum, accessed from oil fields in the region, through the chemical process of destructive distillation.

The Highways Act 1555 in Britain transferred responsibility for maintaining roads from government to local parishes. This resulted in a poor and variable state of roads. To remedy this, the first of the turnpike trusts was established around 1706, to build good roads and collect tolls from passing vehicles. Eventually there were approximately 1,100 trusts in Britain and some 36,800 km (22,870 miles) of engineered roads. The Rebecca Riots in Carmarthenshire and Rhayader from 1839 to 1844 contributed to a Royal Commission that led to the demise of the system in 1844, which coincided with the development of the UK railway system.

The Great North Road near Highgate on the approach to London before turnpiking. The highway was deeply rutted and spread onto adjoining land.

In the late-19th century road engineers began to cater for cyclists by building separate lanes alongside roadways, and to install fauna bridges for wildlife - which will occur on the Mona Vale road as well.

Road design is part of highway engineering. Structural road design is designing a road for its environment in order to extend its longevity and reduce maintenance. The Shell pavement design method is used in many countries for the design of new asphalt roadsides. In structural road design, the main considerations consist of soil parameters, parameters (thickness and stiffness) for the other road foundation materials, and the expected number of times a standard load will pass over. The output of the calculation is the thickness of the asphalt layer.

Road construction requires the creation of an engineered continuous right-of-way or roadbed, overcoming geographic obstacles and having grades low enough to permit vehicle or foot travel, and may be required to meet standards set by law or official guidelines. The process is often begun with the removal of earth and rock by digging or blasting, construction of embankments, bridges and tunnels, and removal of vegetation (this may involve deforestation) and followed by the laying of pavement material.

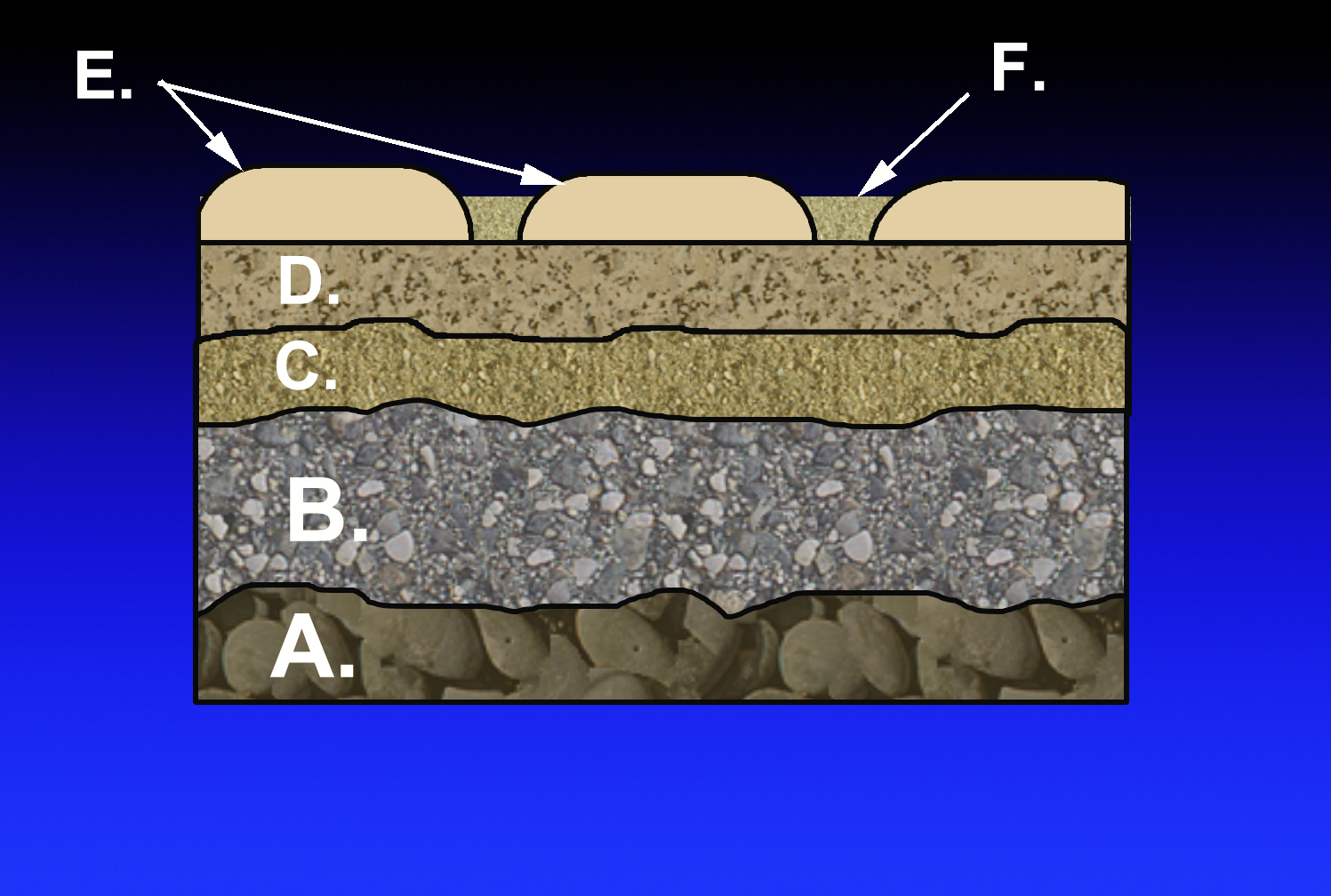

Example: Layers in the construction of a mortarless pavement: A.) Subgrade B.) Subbase C.) Base course D.) Paver base E.) Pavers F.) Fine-grained sand – diagram by and courtesy KDS444

Processes during earthwork include excavation, removal of material to spoil, filling, compacting, construction and trimming. If rock or other unsuitable material is discovered it is removed, moisture content is managed and replaced with standard fill compacted to meet the design requirements (generally 90–95% relative compaction). Blasting is not frequently used to excavate the roadbed as the intact rock structure forms an ideal road base. When a depression must be filled to come up to the road grade the native bed is compacted after the topsoil has been removed. The fill is made by the "compacted layer method" where a layer of fill is spread then compacted to specifications, under saturated conditions. The process is repeated until the desired grade is reached.

All that means a variety of road building equipment is employed in road building to do the different kinds of work involved. As stated above, they are using excavators with rock hammers, backhoes, tipper trucks, small cranes, hammer drills, a roller, street sweepers, chainsaws, light vehicles and light towers. We’ve also seen some bulldozers, some of which have been adapted from tractors!

Here are some you may spot while driving up the Mona Vale road while it's being made wider and bigger, 'upgraded', at present.

Excavator with rock hammer attachment

An excavator is a hydraulic machine used in construction mainly used for digging holes, foundations, and trenches. It is more powerful and efficient than any other diesel-powered heavy construction equipment.

Because they are versatile, they come in different sizes: standard, midi, and mini. Standard excavators are used for bulk transportation and heavy lifting. Midi excavators are used for heavy workloads in an isolated area. Mini excavators are compact, making them great for smaller job areas that require trench-digging, stump removal, and light demolition.

The excavator is not only used in the construction industry but also in forestry and mining as it is quite versatile. If given the right attachments, this machine can be used for demolition, dredging rivers, handling materials, and lifting. Most of you would have seen one of these with what's called a 'bucket' - although these buckets don't look like those we may use in the garden fort watering plants or when washing the car. these ones look like this:

The rock breaker attachment is used to break concrete, rock, or asphalt. Sometimes called a hydraulic hammer attachment, this is like a larger jackhammer. It is used for road repairs, demolitions, landscaping, and trenching. It breaks hard surfaces with the use of 1,000 pounds of impact energy. The 'flushing', 'cooling' and 'lubrication' applied by water for the surface of the bit is very important to ensure the normal working of the bit during the drill bit running.

You can also see that this excavator has what is called a 'track' wheel base instead of tyres, a bit like a tank. Tracks instead of wheels allow the machine to move over all kinds of terrain, some of which would be difficult for a machine with wheels to negotiate.

Excavator with Bucket

Excavators are heavy construction equipment consisting of a boom, dipper (or stick), bucket and cab on a rotating platform known as the "house". The house sits atop an undercarriage with tracks or wheels. They are a natural progression from the steam shovels and often mistakenly called power shovels.

A steam shovel is a large steam-powered excavating machine designed for lifting and moving material such as rock and soil. It is the earliest type of power shovel or excavator. Steam shovels played a major role in public works in the 19th and early 20th century, being key to the construction of railroads and the Panama Canal. The development of simpler, cheaper diesel-powered shovels caused steam shovels to fall out of favor in the 1930s.

Otis excavator, 1841

All movement and functions of a hydraulic excavator are accomplished through the use of hydraulic fluid, with hydraulic cylinders and hydraulic motors. Hydraulic excavator capabilities have expanded far beyond excavation tasks with buckets. With the advent of hydraulic-powered attachments such as a breaker, a grapple or an auger, the excavator is frequently used in many applications other than excavation. Many excavators feature a quick coupler for simplified attachment mounting, increasing the machine's utilisation on the jobsite. Excavators are usually employed together with loaders and bulldozers. Most wheeled, compact and some medium-sized (11 to 18-tonne) excavators have a backfill (or dozer) blade. This is a horizontal bulldozer-like blade attached to the undercarriage and is used for levelling and pushing removed material back into a hole.

This one can be seen moving 'buckets' of dirt

Water Truck

Water trucks are made especially for use in the civil, councils and landscaping industries. The water truck works by being a water storage unit that can hold water for dust control, cleaning and wetting purposes on construction sites through spraying the ground with water canons and cab operated batter sprays. Water can also be used in different applications through hose reels attached to the water truck.

Water trucks are a vital part of most big construction operations. Water trucks come in a range of sizes and designs, with larger trucks able to haul as much as 36,000 litres!

Grid roller

This type of roller is generally a towed unit, and provides high contact pressure but minimal kneading action. They are typically used for the compaction of well-graded coarse soils and weathered rocks, often in subgrade and sub-base road projects.

Grader

Graders are commonly used in the construction and maintenance of dirt roads and gravel roads. In the construction of paved roads, they are used to prepare the base course to create a wide flat surface upon which to place the road surface.

A road grader or a motor grader, is a construction machine with a long blade used to create a flat surface during the grading process. Although the earliest models were towed behind horses or other powered equipment, most modern graders contain an engine, so are known, technically erroneously, as "motor graders". Typical models have three axles, with the engine and cab situated above the rear axles at one end of the vehicle and a third axle at the front end of the vehicle, with the blade in between. Most motor graders drive the rear axles in tandem, but some also add front wheel drive to improve grading capability. Many graders also have optional attachments for the rear of the machine which can be ripper, scarifier, blade, or compactor. In certain countries, for example in Finland, almost every grader is equipped with a second blade that is placed in front of the front axle. For snowplowing and some dirt grading operations, a side blade can also be mounted. Some construction personnel refer to the entire machine as "the blade". Capacities range from a blade width of 2.50 to 7.30 m (8 to 24 ft) and engines from 93–373 kW (125–500 hp). Certain graders can operate multiple attachments, or be designed for specialized tasks like underground mining.

In civil engineering, the grader's purpose is to "finish grade" (to refine or set precisely). The angle, tilt (or pitch) and height of the grader's blade can be adjusted to achieve precision grading of a surface. The "rough grading" is performed by heavy equipment or engineering vehicles such as scrapers and bulldozers.

Graders are commonly used in the construction and maintenance of dirt roads and gravel roads. In the construction of paved roads, they are used to prepare the base course to create a wide flat surface upon which to place the road surface.

Front End Loader

A front-end loader is a tractor with a large, hinged bucket mounted on the front at the end of a pair of jointed arms, for scooping and loading earth, gravel, debris, etc. Front end wheel loaders are one of the most versatile machines in use today, having a diverse application across agriculture and construction industries - such as in building a road.

They are used to move materials into or onto another type of machinery (such as a dump truck, conveyor belt, feed-hopper, or railroad car). There are many types of loader, which, depending on design and application, are called by various names, including bucket loader, front loader, front-end loader, payloader, scoop, shovel, skip loader, wheel loader, or skid-steer.

The major components included in a loader are the engine (diesel in almost all cases), the hydraulic components (such as pumps, motors and valves) and the transmission components (gearbox, axles, wheels/tracks, pumps, motors, etc.). The engine runs both the hydraulics and the transmission, and these in turn move the front attachment (a bucket, forks, sweeper, etc.) to manipulate the material which we are handling (sand, gravel, cereal, manure or anything else) and the wheels or tracks to move the machine around the jobsite.

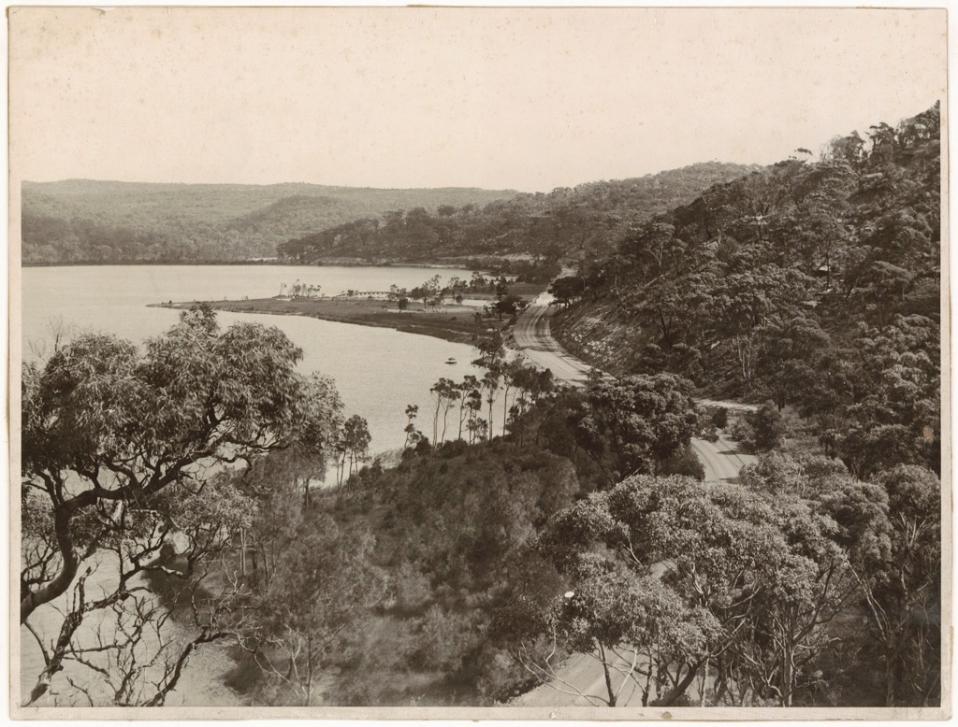

So that's a few of the big machines doing all that work along Mona Vale road at present - very interesting stuff, and we'll bring you more as the project develops; a page or pages of before and after photos to do comparisons would be interesting, as would some more of those machines or how they're doing all the work to build a road. There's also a wealth of information you can find to see how roads were built in the past. The New South Wales Department of State Archives and Records has thousands of old photos of road building done here from the past, one example from their files:

There is also the NSW Roads and Maritime Department has some great videos of past road builds as well.

Roads and Maritime's YouTube channel

Finally, it’s good to know we’re not the only ones interested in all this road-building, landscape changing information,. Did you know the the NSW Roads and Maritime holds an extensive archive of historic films related to road building projects.They are in the process of digitising this archive, and publish the films on our YouTube channel as they become available. Visit: https://www.youtube.com/user/RMSRoadProjects

Here’s a few old examples that we think you may like – the Construction of the Great Northern Highway from Hornsby to Hawkesbury River (1928) and Testing of Bascule Span for Spit Bridge over Middle Harbour (1958). There is a Pittwater Online History page on Roads To Pittwater: The Sandspit Punt and Spit Bridge as part of that Pittwater Roads series, which shares some insights as well.

This first is a silent film but it shows you how much has changed around here and gives you views of the terrain around that wonderful old bridge up the Hawkesbury. A few years ago a Pittwater Online News History page on the Hawkesbury Bridge was run to celebrate the 70 year anniversary of he second Hawkesbury Bridge, and there's a video on that embedded as well on that page.

Construction of the Great Northern Highway from Hornsby to Hawkesbury River (1928)

Testing of Bascule Span for Spit Bridge over Middle Harbour (1958)

Also available:

History Insights

- Pittwater Roads II: Where the Streets Have Your name - Scotland Island

- Pittwater Roads II: Where the Streets Have Your Name - Newport Beach

- Pittwater Roads II: Where the Streets Have Your Name - Clareville

- Pittwater Roads II: Where the Streets Have Your Name - Avalon Beach

- Pittwater Roads II: Where the Streets Have Your Name - Warriewood

- Pittwater Roads II: Where the Streets Have Your Name - Elanora Heights, Green Hills and Ingleside

- Pittwater Roads II: Where the Streets Have Your Name - Mona Vale

- Pittwater Roads II: Where the Streets Have Your Name - Bungan

- Pittwater Roads II: Where the Streets Have Your Name - Bilgola

- Pittwater Roads II: Where the Streets Have Your Name - Coaster's Retreat and The Basin

- Pittwater Roads II: Where the Streets Have Your Name - Great Mackerel Beach

- Pittwater Roads II: Where the Streets Have Your Name - Whale Beach

- Pittwater Roads II: Where the Streets Have Your Name - Palm Beach

- Roads In Pittwater: The Bay View Road

- Roads In Pittwater - The Barrenjoey Road

- Motor Car Tours To And In Pittwater Show Us The Way This Place Once Was

- Roads To Pittwater: The Wakehurst Parkway Along Old Oxford Falls Track

- Roads To Pittwater: The Pittwater Road

- Roads To Pittwater: The Sandspit Punt and Spit Bridge

- Roads To Pittwater: The Mona Vale Road

- My Holiday by Charles de Boos – 1861

Mona Vale Road Upgrade

- Delivering Infrastructure - Upgrading Mona Vale Road - April 2014

- Upgrades To Start on Mona Vale Road - July 2014

- Once Was Barrenjoey - Can Community Reduce Fauna Road Deaths - August 2014 - Community Consultation on stage 2 (between Mona Vale and Ingleside) for Mona Vale Road upgrades is expected to begin later this year and will also include fauna connectivity options.

- Community Feedback Sought On Mona Vale Road Upgrade - October 2014

- Angus's Onion Orchid at Ingleside?? by David Palmer, PNHA - October 2015

- Bill To Facilitate Mona Vale Road Upgrades Passes: Vital Fauna Bridge Discussed - Stage 3, Mona Vale Road Upgrade- West, one step closer - June 2016

- NSW Government Funding To Commence $90M Upgrade Of Mona Vale Road East - June 2016

- Funding Secured To Commence Mona Vale Road Upgrade - from Office of Hon. Rob Stokes, MP for Pittwater - June 2017

- Reducing Roadkill On Mona Vale Road by David Palmer, Pittwater Natural Heritage Association - September 2017

- Front Page Issue 330: Jumping For Joy: Fauna Crossing For Mona Vale Road Confirmed - September 2017

- Mona Vale Road East Upgrade: Proposed Lease Of Land To Roads And Maritime Services (RMS) - Council Invites You to Have Your Say - November 2017

- Plans Accelerate For Mona Vale Road East Upgrade - from Office of The Hon. Rob Stokes, MP for Pittwater - March 2018

- Sydney's First Fauna Overpass To Be Installed On Mona Vale Road + RMS March 2018 Mona Vale Road update

- Roads To Pittwater: The Mona Vale Road (History page) - September 2018

- Contract Awarded For Mona Vale Road Upgrade - from Office of the Hon. Rob Stokes, MP for Pittwater - November 2018

- Upgrade Of Mona Vale Road East To Commence This Month - an overview of what to expect - January 2019

- Mona Vale Road Upgrade - Changed Traffic Conditions Reminder - from Office of Rob Stokes, MP for Pittwater - March 2019

- Mona Vale Road East Upgrade: Some Progress Photos - May 2019 Record

- Mona Vale Road Truck Arrestor Bed Miscalculation? - report by Phil Walker and John Illingsworth/Pittwater Pathways - June 2019

- Mona Vale Road Upgrade Update: Fauna Fencing To Be Installed During Construction + June Night Works - June 2019

- Mona Vale Road East Upgrade: September 2019 Update - and Pictorial Record Of Works - September 2019

- Mona Vale Road East Upgrade: October 2019 Update In Pictures

- Mona Vale Road East Upgrade Calls In Sydney Wildlife Volunteer To Relocate Lapwing Plovers Nest: Eggs Hatch! - October 2019

- Mona Vale Road East Upgrade Update - To December 2019: Our last day of work for 2019 will be Friday 20 December and we will return to work on Monday 6 January 2020

- Mona Vale Road East Upgrade: January 2020 Update and Photographic Record Of Works

- Mona Vale Road East Upgrade: Mid to Late February Notice and Pictorial Record of Works and Changes - February 2020

- Mona Vale Road East Upgrade: May 2020 Pictures Record