July 21 - 27, 2013: Issue 120

Hand Plough and Stump Jump Ploughs - The Australian Plough

We’ve spoken to Trevor Goodacre lately and he has let us know there’s a few more objects that have been added to Trevor’s Museum. So before we go and catch up with this gentleman and see what else he has acquired, we thought we’d bring you one from a few years back that we haven’t had an opportunity to share yet.

We’ve spoken to Trevor Goodacre lately and he has let us know there’s a few more objects that have been added to Trevor’s Museum. So before we go and catch up with this gentleman and see what else he has acquired, we thought we’d bring you one from a few years back that we haven’t had an opportunity to share yet.

This is a hand plough, a tool that once used in farming for initial cultivation of soil in preparation for sowing seed or planting to loosen or turn the soil. Ploughs were, and still are in some places, initially human powered, but the process became considerably more efficient once animals were pressed into service. The first animal powered ploughs were undoubtedly pulled by oxen, and later in many areas by horses (generally draught horses) and mules, although various other animals have been used for this purpose. They wer made of wood to begin with and iron later on.

They have been a basic instrument for most of recorded history, and represent one of the major advances in agriculture. When agriculture was first developed, simple hand-held digging sticks and hoes were used in highly fertile areas, such as the banks of the Nile where the annual flood rejuvenates the soil, to create drills (furrows) to plant seeds in. Digging sticks, hoes, and mattocks were not invented in any one place, and hoe-cultivation must have been common everywhere agriculture was practiced. Hoe-farming is the traditional tillage method in tropical or sub-tropical regions, which are characterized by stony soils, steep slope gradients, predominant root crops, and coarse grains grown at wide distances apart. While hoe-agriculture is best suited to these regions, it is used in some fashion everywhere. Instead of hoeing, some cultures use pigs to trample the soil and grub the earth.

The primary purpose of ploughing is to turn over the upper layer of the soil, bringing fresh nutrients to the surface, while burying weeds, the remains of previous crops, and both crop and weed seeds, allowing them to break down. It also aerates the soil, allows it to hold moisture better and provides a seed-free medium for planting an alternate crop. In modern use, a ploughed field is typically left to dry out, and is then harrowed before planting.

In industrialised countries, the first mechanical means of pulling a plough were steam-powered (ploughing engines or steam tractors), but these were gradually superseded by internal-combustion-powered tractors.

In 1763 a Berwickshire man, John Small, first applied mathematical calculations and science to the mouldboard shape. He experimented with varying mouldboard curvatures and patterns, eventually producing a universal cast iron shape that would turn the soil more effectively with less draft, wear and strain on the ploughman. Over the years this 'Scots Plough' as it was know, was the beginning of the plough we all know today.

Trevors looks like a smaller version of the stump jump plough - a purely Australian invention. The stump jump is internationally recognised as one of the most important agricultural inventions since settlement in Australia. It was invented by South Australian farmers Richard and Clarence Smith of Kalkabury on the Yorke Peninsula, while clearing their land. The dense Mallee eucalyptus bush was difficult to clear because of its deep roots. Before the advent of ploughs these mallee stumps had to be removed by hand, but with the increase of wheat farming in country South Australia it was essential to find a machine that could cope with the difficult terrain.

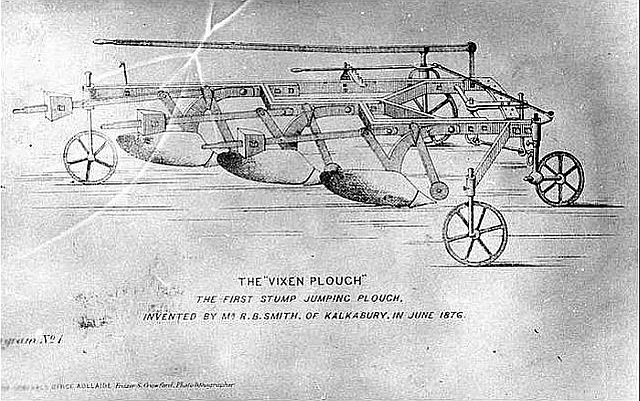

In 1876, after breaking a bolt on his plough and finding that it rode over a stump rather than becoming stuck or breaking on it, Richard Smith first had the idea of a new type of plough which would “jump over” the stumps rather than be stuck in or behind them. His first invention, a three furrow plough, was too heavy, but after some modifications by his brother, it became a workable machine. Over the next few years Richard Smith continued to work on improving the design and began the manufacture of the plough in 1880. The stump jump plough was made up of a row of hinged blades or shares, and when the blades struck a mallee stump or stone in the ground, they rose up to pass over the obstacle. Weights pushed the blade back down into the soil to continuing the furrow after the blade had “jumped over” the root or stone. This new plough had wide applications and revolutionised agricultural practices at the time.

In 1882 the South Australian Parliament declared Richard Bowyer Smith as the inventor of the stump jump plough, and he received a reward of £500. Richard moved to Western Australia and established a manufacturing business. His brother Clarence remained in South Australia, married and set up an agricultural machinery business in Ardrossan, which his sons took over after his death in 1901. His Ardrossan business did not survive the Great Depression of the 1930s

In English, as in other Germanic languages, the plough was traditionally known by other names, e.g. Old English sulh, Old High German medela, geiza, huohili, and Old Norse arðr (Swedish årder), all presumably referring to the scratch plough (ard).

The current word plough comes from Old Norse plógr, and therefore Germanic, but it appears relatively late (it is not attested inGothic), and is thought to be a loanword from one of the north Italic languages. Words with the same root appeared with related meanings: in Raetic plaumorati "wheeled heavy plough" (Pliny), and in Latin plaustrum "farm cart", plōstrum, plōstellum "cart", andplōxenum, plōximum "cart box". The word must have originally referred to the wheeled heavy plough which was known in Roman northwestern Europe by the 5th century a.d. (1)

Farming Implements. Just arrived-n. New Stock of the Celebrated New Zealand Double-furrow and Single-furrow Ploughs, together with a large stock of Plough Shares, Plough Wheels, Wheel-coulters, and other Fittings; also on hand-Single furrow Ploughs, Harrows, Horse Hoes, Mowing Machines, and Corn Shelters. Farming Implements. (1893, October 24). Warwick Argus (Qld. : 1879 - 1901), p. 3. Retrieved from http://nla.gov.au/nla.news-article76644214

A plan of the a stump-jump plough from 1876; from State Library of South Australia

IMPROVED METHODS. The new century gardener starts with a full line of the finest garden tools. In place of the old-time heavy plough, and the rigid, clumsy wooden cultivator, we now have lightweight ploughs, adjustable steel frame horse hoes, hand wheel-hoes, hand ploughs, and hoes and rakes of every description. There are also seed drills, and seed drills with fertiliser attachments, and every device that science and skill could invent. And then there are the disc, the spike and the spring tooth harrows. Planting potatoes the old way is alright for small patches of an acre or so, but for selling commercially they cost too much that way. At one passage now with a modern potato planter a furrow is opened, seed is dropped, fertiliser is applied and mixed with earth, and the seed is covered. Figure out how many men and horses it would take to do this work in the "old way," Can a potato grower afford to follow his grandfather's method? IMPROVED METHODS. (1901, June 28). Euroa Advertiser (Vic. : 1884 - 1920), p. 2 Supplement: Supplement to the Euroa Advertiser. Retrieved from http://nla.gov.au/nla.news-article65536453

WHICH PLOUGH— AND WHY? I have looked, in vain in print(writes 'H.S.') and I have asked my bush neighbors without success, for some lucid explanation of the relative values of the different patterns in ploughs. I think there are many others who would like to know. Surely the choice of a plough should not as at present be largely a matter of fad or fancy. Why is one make of plough preferred in one district and quite another make elsewhere? Is it a matter only bf different soil. This is the kind of information I gain from an old hand:— 'Disc ploughs are horse killers. It is true they will turn up stiff land when no others will look at it; but it is not wise to turn land in a dry state. The high mould-board plough is also a horse killer, but not so sudden. It ploughs and harrows at the same time; but you must have the extra power there for the extra work done. The old, long mouldboard is the champion for man and beast. Cheap shares and repairs. No knocking off for a week in a busy time while a broken part comes from Sydney. As I'm afraid, my old friend would commend stage coaches in preference to railway travelling.1 I have doubts about the above. Will some of your readers who are experienced with shapes of ploughs, please give us some light on the question ? WHICH PLOUGH—AND WHY?. (1909, July 2). The Farmer and Settler (NSW : 1906 - 1957), p. 8. Retrieved from http://nla.gov.au/nla.news-article115963273

Mouldboard plough: It was once thought that to grow crops regularly in less fertile areas, the soil must be turned to bring nutrients to the surface. A major advance for this type of farming was the mouldboard plough which not only cuts furrows with a share (cutting blade) but turns the soil. A coulter (or skeith) could be added to cut vertically into the ground just ahead of the share (in front of the frog), a wedge-shaped cutting edge at the bottom front of the mouldboard with the landside of the frame supporting the undershare (below-ground component). (1).

1. Plough. (2013, July 6). In Wikipedia, The Free Encyclopedia. Retrieved from http://en.wikipedia.org/w/index.php?title=Plough&oldid=563158979

_______________________________________________________________________

This steam ploughing engine is an example of the world's first successful method of powered cultivation, developed by John Fowler of Leeds, England in 1863. This involved ploughing with two traction engines, each with a drum carrying cable suspended beneath its boiler. Located on either side of a field, the engines took turns to drag the cable, to which a special balance plough was attached.

This steam ploughing engine is an example of the world's first successful method of powered cultivation, developed by John Fowler of Leeds, England in 1863. This involved ploughing with two traction engines, each with a drum carrying cable suspended beneath its boiler. Located on either side of a field, the engines took turns to drag the cable, to which a special balance plough was attached.

Traction engines were developed by the early 1860s, but they were too heavy to pull ploughs directly over the soil. By the mid 1860s Fowler had devised his basic ploughing engine design which was to remain, with improvements, until the last ploughing engine left Fowler's works in England in 1933, superseded by the development of the internal combustion engined tractor.

Ploughing engine sets were very costly to buy and operate in Britain. Far more were exported around the world, to the German, Austro-Hungarian, Russian and Turkish empires, developing the great potential of their vast land resources, and to Egypt, Tunis, South Africa, the Transvaal, Mozambique, Australia, Hawaii, Peru and Brazil.

Owing to the nature of land use in Australia, steam cultivation was not common here. Most holdings were too large, the country was too rough and fuel and water supplies were too scant in many areas. It has been estimated that only about one hundred Fowler ploughing engines were used throughout Australia. The first to operate was in the 1860s in South Australia, closely followed by Victoria, Western Australia, and then Queensland in 1881 and New South Wales in 1882.

Many ploughing engines were not imported for agricultural purposes but for construction of large earth tanks. These techniques were developed for outback sheep stations in the 1870s. During the 1880s some travelling stock routes were improved by government-owned Fowler ploughing engines with excavating scoops.

Steam ploughing was used during the development of the irrigation areas along the Murray and Murrumbidgee Rivers. During the 1920s ploughing engines were used by the Water Conservation and Irrigation Commission to clear and plough land for soldier settlers around Griffith. Another big user was the Queensland sugar industry. where steam ploughing was used on plantations until World War II.

The museum's ploughing engine is the left hand side of a pair of wood-burning engines, Nos. 5933 and 5934, built at John Fowler & Co.'s Steam Plough Works, in Leeds, England in 1889. They were ordered by Michael O'Shaunnassy for his Jerilderie property in New South Wales. The engines were later sold to the pastoralist and philanthropist Sir Samuel McCaughey (1835-1919). McCaughey was a significant sheep breeder in New South Wales and owned numerous stations. In 1900 he bought a North Yanco property and it was there that he employed the two Fowler ploughing engines. He constructed a complex irrigation system with some 200 miles (321.9 km) of channels to irrigate 40 000 acres (16 188 ha) on which he grew lucerne and other fodder crops. In 1912 McCaughey sold the ploughing engines to the Water Conservation and Irrigation Commission for operation at Leeton to remove silt from water channels and to deepen watercourses in catchment areas.

In the 1930s the two engines were separated and the museum's engine, No. 5933, was used one farm for water pumping and another for driving a circular saw. In 1965 the engine went to the Goulburn Steam Museum for display and it was subsequently acquired by the Powerhouse Museum and restored to steaming condition. It has been displayed at steam rallies around Sydney to promote the museum.

Goodman, Ross, 'The Rebirth of Fowler ploughing engine 5933' in "Steaming : The Magazine of the National Traction Engine Trust", Vol.36, No.1, Winter 1992/93, pp.12-15.

Lane, Michael, 'John Fowler and the Company he Founded' in "Steaming :-The Journal of the National Traction Engine Club, (UK)", Vol.23 No.2, March 1980, pp. 73-87; Vol.23, No.3 , June 1980, pp.145-53; Vol. 23 No.4, Sept 1980, pp. 221-28.

Lane, M.R. "The Story of the Steam Plough Works", Northgate Publishing Co. Ltd, 1980.

Margaret Simpson

Assistant Curator, Transport

Read more: http://www.powerhousemuseum.com/collection/database/?irn=211510#ixzz2YvmY0jb5 . Under Creative Commons License: Attribution Non-Commercial

|

|

Copyright Pittwater Online News, 2013. All Rights Reserved.